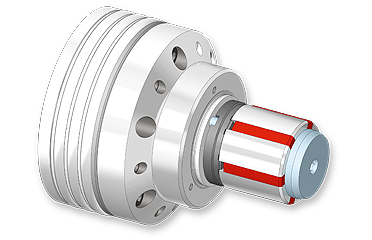

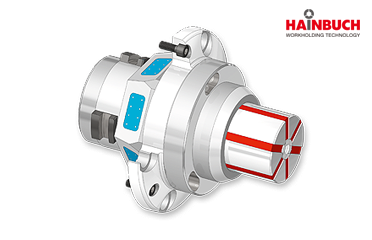

反張夾頭

Mandrel MANDO Chuck

標準反張夾頭,內徑夾持專家

產品詳敘

Hainbuch Mandrel MANDO Chuck

內孔夾持,不再傷腦筋!

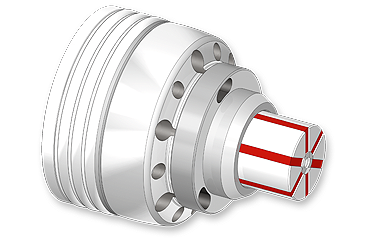

亮點

- 夾固環上橡膠經硫化處理,具吸震效果。

- 軸向後拉力承靠著工件止動器,確保工件穩固夾持。

- 小徑夾持也有大夾持力。

- 僅需八種反張模組尺寸,即可涵蓋夾持範圍8-100mm。

- 同心精度可能達到< 0.01mm。

- 硫化處理橡膠設計,夾固環膨脹範圍大。

- 標準止動器,可自行加工至所需尺寸。

- 標準夾固環,可自行修整至想要的尺寸。

- 具備HAINBUCH 夾具系列的特色: 平行夾持、最佳功能

- 堅固、高夾持力,以及耐磨耗。

簡介

完整的加工常缺乏有效率的內徑夾持而失敗。很多狀況下, 夾爪夾具是個臨時替代的方案, 傳統的溝槽式筒夾, 在精度、穩定性與膨脹行程也多有限制, 除非您使用的是H A I N B U C H 反張夾具系統。HAINBUCH反張夾具系統導入最新夾持技術,即使是在最困難的應用上,其表現仍然另人信服。HAINBUCH反張夾具的中心元件是經硫化處理過的夾固環。傳統溝槽式筒夾係由彈簧鋼製成,因此筒夾硬度也僅限於此,其低硬度在夾持工件時,筒夾彎曲變形成為一種必然。而HAINBUCH夾固環,係由表面硬化處理過的鎳鉻合金鋼製成,因此硬度極高、耐磨性與穩度性都極佳。所有的接觸表面皆一起研磨製造,以確保最理想的同心度。

影片

Efficient and economical

Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications.

High holding power by HAINBUCH technology

The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, therefore they are soft and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid. All contact surfaces are completely ground in one operation guaranteeing optimum concentricity.

Key advantages

- Vibration dampening due to vulcanized segmented clamping bushings

- Workpiece stabilization through axial draw force applied against the workpiece end-stop

- Extremely high clamping force even at the smallest clamping Ø

- Clamping ranges from Ø 8 – 120 mm with only 8 mandrel sizes

- All mandrels prepared for air sensing control