TOPlus 油壓六角夾頭

TOPlus Chuck

創新型夾頭設計,更大夾持力

產品詳敘

Hainbuch TOPlus Chuck

六角更穩固!

亮點

- 比圓形夾固頭高出25%的夾持力

- 六角形夾固頭可全面貼合夾具,剛性超高

- 夾固頭貼合夾具,抗污、抗屑效果佳

- 同心度可達 < 0.015 mm

- 夾頭材料具緩震特性

簡介

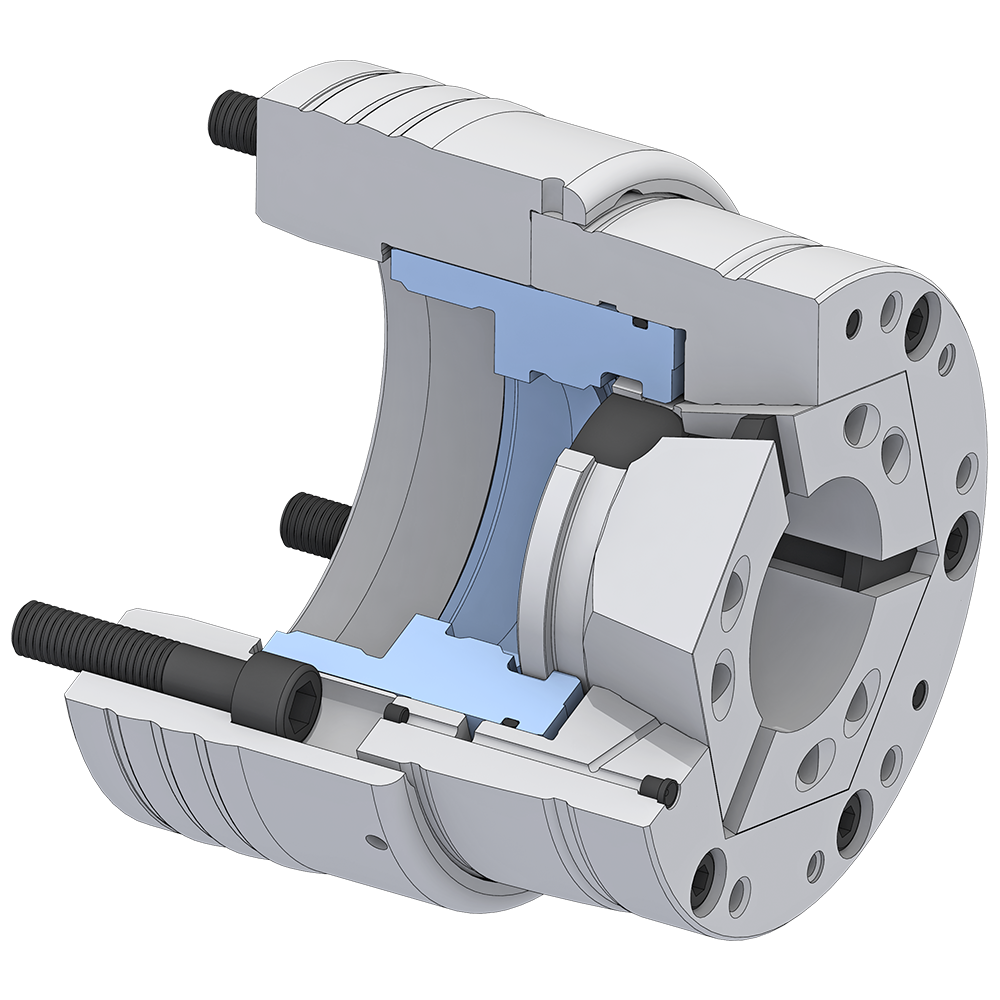

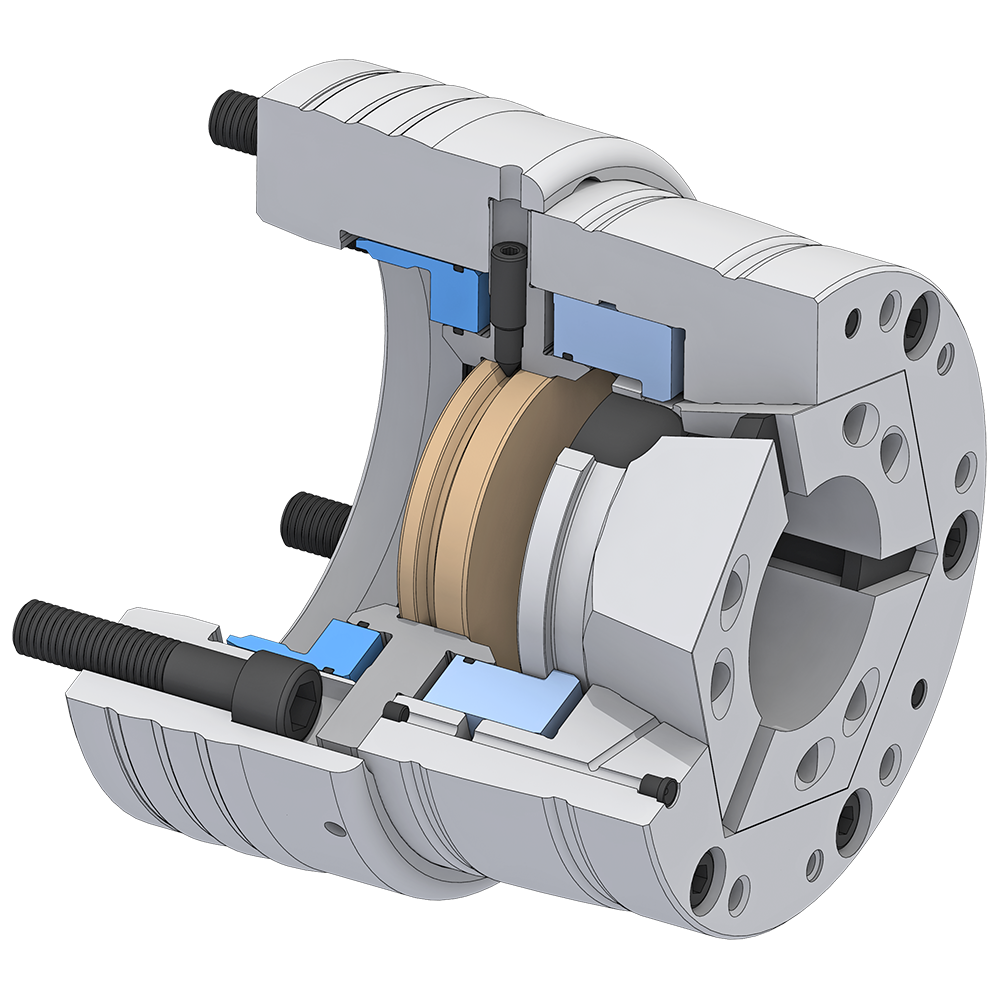

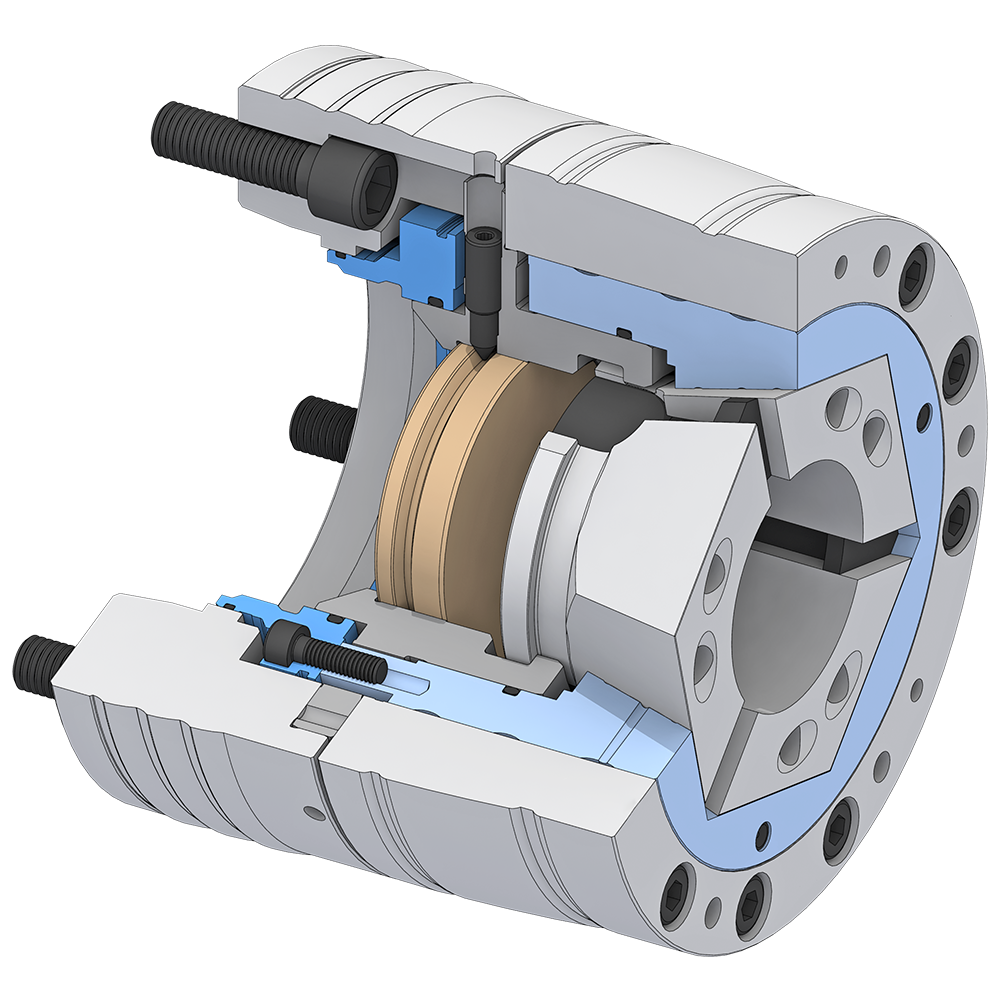

灰塵、細屑或任何髒污都會造成加工上的阻礙,至少這是使用傳統夾頭時會發生的狀況,但托普勒司夾頭可不是這麼一回事。不同於夾頭本體的錐面,托普勒司夾頭由六個圓錐形鋼片搭配礦物聚合物形成三角錐幾何形狀。一如夾頭,夾固頭有外六角面,可緊密組裝入並貼合夾頭內面。這表示夾頭幾乎可將髒污完全隔絕於外。另若需要潤滑, 則可使用單潤滑噴頭。由於表面壓力的減少與夾持面間的完全密合, 使得托普勒司夾頭徑向夾持力高於SPANNTOP整整25%。因此托普勒司更適用於素材工件、熔鑄件或鍛造件夾持。托普勒司夾頭相較於一般鐵製夾頭在重量上也減少很多,因此有較低的總慣性扭矩, 特別有利於高速加工。夾頭本身的材料也有緩震的特性。托普勒司夾頭非常適用於重加工與乾切削。

夾頭尺寸

26 / 40 / 52 / 65 / 100

通孔型夾頭 (Modular):通孔設計,適用棒材與管材

- 平行/圓筒式夾持

- 後拉作動,與傳統夾頭相比,可實現更高剛性的夾持力

- 高堅固性

- 磨耗性小

- 簡單換模

- 同心度< 0.01 mm

止動型夾頭 (Pull back): 內附固定式止動器,適用塊狀素材。拆卸止動器後即為通孔,適用棒材。

- 軸向拉力並止於止動器,確保穩固夾持(短徑夾持也適用!)

- 慣性損失小

- 高堅固性

- 絕佳的夾持力

- 換模後重覆同心度高

- 簡單機構卻有更佳的力轉換

- 短夾持距離工件也適用

- 拆卸止動器後即可變為棒材用夾頭

軸向零移位夾頭 (Deadlength):固定式夾固頭設計,且具有通孔與止動器之功能。

- 徑向夾持,工件無軸向運動

- 短軸環(short collar or shoulder)工件亦適用

影片

Power chuck TOPlus (Six to win)

Unequalled rigidity

Up to 25 % more clamping force and higher output – with the same clamping cylinder that is used to actuate our SPANNTOP chucks. The pyramid arrangement of glide surfaces makes it possible. The clamping headrests with full-surface contact in the TOPlus chuck body – even with large workpiece tolerances.

Insensitive to dirt

In addition, this geometry ensures that TOPlus is significantly less sensitive to contamination than previous chuck/clamping head solutions, and with a concentric precision of approx. 0.015 mm [for chuck size 65]! Thus TOPlus is even better suited for raw material, cast and forged parts, as well as fine-particle non-ferrous metals such as brass. Therefore, all-round optimized values make the chuck an ideal partner for modern manufacturing strategies and state-of-the-art machine tools.

TOPlus – simply revolutionary!

Key advantages

- 25 % higher holding power than SPANNTOP

- Unequalled rigidity due to full-surface contact of the clamping segments

- Superior resistance to contamination because of the clamping head geometry

- Absorbs vibration

- Optimal lubrication thanks to lubricating grooves in the clamping head reception

- Minimal inertia loss compared to 3-jaw chucks